Breww provides you with tools to help manage your yeast batches, including the ability to crop, pitch and measure and report on cell counts over generations.

Starting a yeast batch

You can start a yeast batch in one of two ways:

- Started from existing yeast stock in your inventory

- Extracting (cropping) directly from a beer batch

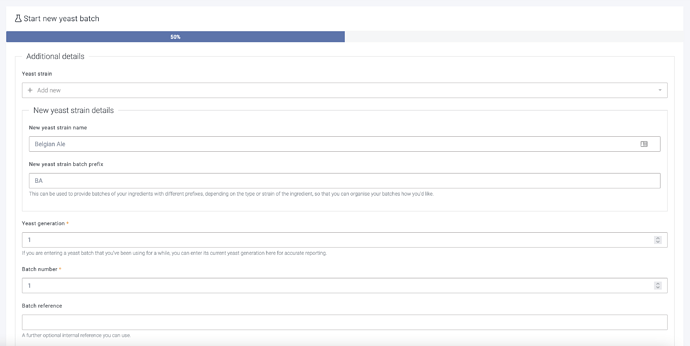

To begin a new yeast batch from existing yeast stock, go to Production > View > Yeast/ingredient batches > Start new batch > Yeast.

When creating a new yeast batch, you’ll be able to specify its “Strain”, the batch’s current generation, and the stock items it was started from - amongst other key bits of information.

A new yeast batch will also be started if you extract yeast from a beer batch that has had no yeast batches added to it.

Adding yeast to a beer batch

You can add your yeast batch to a beer batch from the yeast batch’s page, by going to Actions > Add to beer batch. You can choose to add as much or as little of the yeast batch as you would like. Breww is flexible enough to allow you to split a yeast batch over multiple batches of beer.

You can view all yeast batches added to a beer batch under the Ingredients tab on the beer batch.

Extracting (cropping)

You can extract yeast back out of your beer batch by clicking Actions > Extract yeast/ingredient. You can extract yeast into empty vessels or vessels filled with another yeast batch. Extracting the yeast batch will increase its current generation by one automatically.

Usage and Genealogy

At any point, you can view the usage and genealogy of the yeast batch under the Genealogy tab on the yeast batch.

Cost calculations

In order to evenly distribute yeast costs across multiple batches, when adding a purchased stock item to the yeast batch you will be asked over how many beer batches you would like to spread the cost. If you split the yeast batch amongst multiple beer batches, they will proportionally share one usage-worth of the cost.

For example, in the above screenshot, the expected usage is four and the total cost is £100. Initially, the yeast batch is split 50:50 between two batches so each beer batch receives (£100 / 4) / 2 = £12.50. The next beer batch then uses the entire yeast batch, so it receives (£100 / 4) / 1 = £25 of cost.

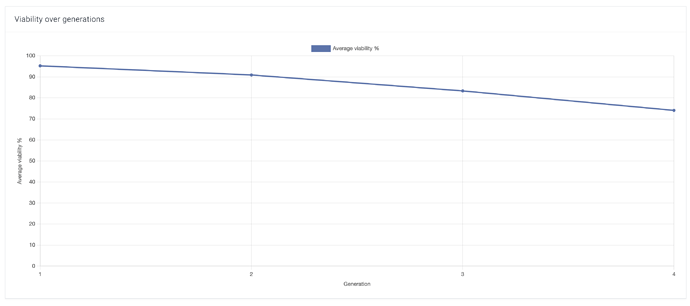

Viability reporting

You can record cell counts for your yeast batch from under the Cell counts & viability tab. As you record more cell counts and use your yeast batch across multiple beer batches, Breww will generate a graph showing the yeast’s viability over generations.

Why is it called yeast/ingredient batches?

Although the primary use of this functionality is for managing yeast batches, it can also be used to manage any ingredient that you pre-prepare and use over multiple beer batches. For example, if you prepare a Fruit puree with multiple ingredients that you then use in multiple beer batches, you could create a “Fruit” ingredient batch. You could then add this ingredient batch to all of those beer batches and see their cost spread proportionally amongst them.