In Breww, assembling products is the process of building a mixed-pack or multi-pack product from the source components. For example, if you have bottles of Beer A and Beer B in stock, but have sold a product that contains 3 bottles of each, in order to deliver the mixed-pack product, it will first need to be assembled from these two stocks of bottles. Likewise, if you sell a 12 pack of bottles and only have “singles” in stock in Breww.

Disassembling refers to the opposite process - for example, if you have some 24 packs of a beer in stock and a customer has ordered an individual bottle, you may need to split one 24 pack into 24 individual bottles to fulfil the order. The remaining 23 bottles will be in stock still for subsequent orders (or to be assembled into other products).

Automatic assembly and disassembly of products

Breww can assemble and disassemble products automatically to fulfil your orders. (We recommend using this to save you time, but if you don’t want to do this, you can disable these options and manually manage your products.)

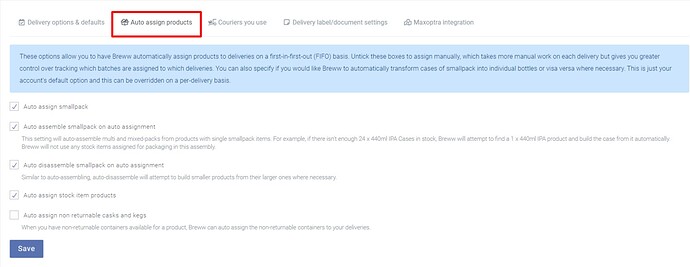

To let Breww automatically handle this for you, go to Settings → Delivery settings → Auto-assign products (tab). Product reformatting will occur at the point of stock assignment within an order if the auto-assemble/disassemble tool is enabled. When reformatting stock, Breww takes into account the “theoretical max” stock value - we have a help page on that here.

If you want to assemble or disassemble products manually, see the processes described below.

Manual assembly of products

Single smallpack products can be assembled into a multi-pack product in the same way by going to the single smallpack product page, clicking Actions and then clicking Assemble product.

Manual disassembly of products

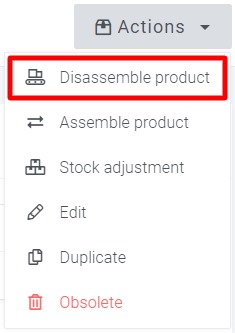

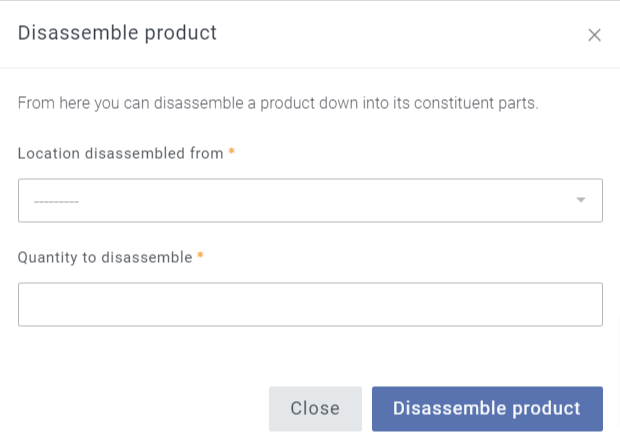

Smallpack multi-pack products can be disassembled by going to the multipack product page, clicking Actions and then clicking Disassemble product. This will then allow you to pick the location that the product is being disassembled from and the quantity.